Ever wondered how to optimize your cooling system without expensive physical testing? Imagine a tool that can predict how fluids like air and water will flow around objects, helping you design better and improve efficiency. This is where Computational Fluid Dynamics (CFD) comes in.

What is Computational Fluid Dynamics (CFD) Analysis?

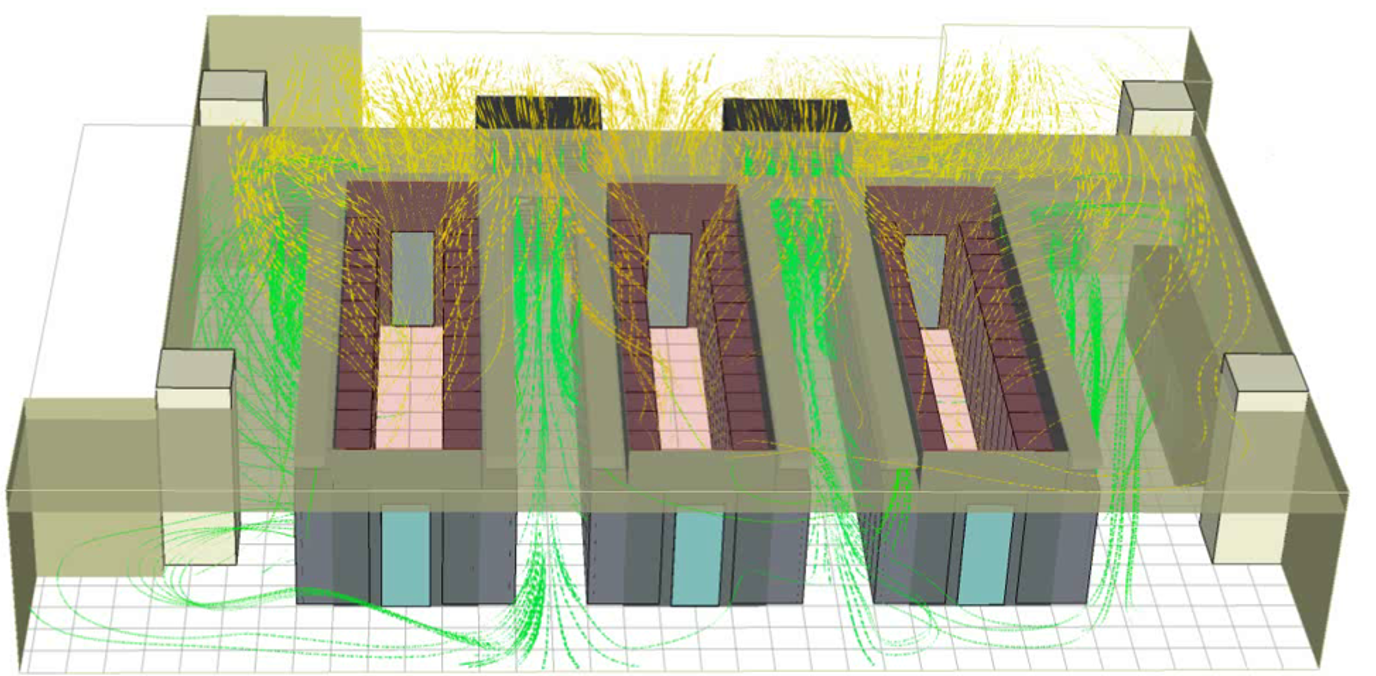

Computational Fluid Dynamics (CFD) is a powerful engineering tool that uses advanced computer simulations to predict and analyze the behavior of fluids like air, water, or oil. This allows engineers to virtually create a digital replica of a system and calculate fluid properties like pressure, temperature, and velocity at any point without using physical prototypes.

Why CFD Stands Out in Heat Transfer Analysis?

Traditional heat load testing often relies on building and testing physical prototypes, which can be a costly and time-consuming process.

CFD analysis offers a powerful alternative, allowing you to:

Predict heat transfer patterns with unparalleled accuracy

CFD visually identifying areas prone to overheating or uneven cooling. This invaluable insight empowers you to make informed design decisions before fabrication begins.

Optimize cooling system design virtually

Experimenting with different configurations to find the one that delivers the most efficient heat transfer. This streamlines the development process, saving valuable time and resources.

Reduce development time and costs significantly

By identifying and addressing potential issues early on through CFD simulations, you can minimize the need for physical prototypes and revisions, ultimately leading to significant cost savings.

How Does it Work?

The CFD process involves several key steps:

Pre-processing

Defining the geometry of your system, setting up the simulation parameters, and specifying the fluid properties.

Solving

The CFD software utilizes complex mathematical equations to calculate the flow of the fluid throughout the defined geometry.

Post Processing

Analyzing the results, visualized through color contours and graphs, to understand the fluid behavior and identify areas for improvement.

By leveraging CFD analysis, you can gain valuable insights into your cooling system, leading to optimized designs, improved efficiency, and reduced costs.

Our Capabilities

At CITEC International, our CFD specialists perform multiple stimulations for each system. Each produces intricate models that yield actionable insights while remaining flexible for many variables in your environment. More than just model crafters, your specialists help you to understand the results and determine the next best course of action.